World Wide Suppliers of Industrial Sapphire&Ruby Precision Parts

Sapphire to Metal for Fluidic,Metrology&Medical Components

ISO 9001:2019 Mfg&Managment Certified Companies

-

- Sapphire Lens

- IPL Light Guides

- Sapphire Prism

- Zirconia Ceramic Parts

- Single Crystal Silicon Carbide(SiC 6H/ 4H)

- Optical Windows

- Optical Lens

- Sapphire Substrate&Wafer

- CMM Styli - Probe Tips

- Sapphire Orifice Jewel

- Sapphire Windows

- Jewel Bearing

- Sapphire Tube&Rods

- Balls&Semisphere

- Ruby Orifice Nozzle

- Sapphire&Ruby Assembly Parts

- Sapphire&Ruby Nozzle

- Custom Shaped Sapphire Parts

ISO 9001:2019 Certified

information

We serve demanding customers worldwide.With advanced CMM device and innovative

production techniques & systems integrate latest technologies to meet the evolving

needs of our customers.

Contact Details

Chonghong Industries(Microwork)Ltd.

1803,2006,Huachuang Intl Commerce Building

Honghuang 10th Road Jiangbei District

Chongqing China 400020

Tel: (0086-023) 67937146Fax: (0086-023) 89119130

Cellphone:0086-18623135040

COMPANY NEWS

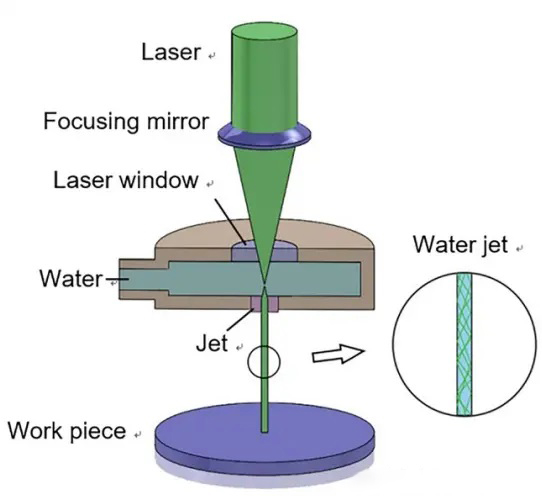

Water Guided Laser Jet

Water-guided laser cutting technology is a processing method that combines high-energy pulse lasers with guided water jets. By coupling laser energy into a water jet, it achieves cutting and processing of various materials. This technique effectively reduces thermal damage and material deformation, making it suitable for precision machining and high-quality cutting applications.

Advantages of Water-Assisted Laser Technology

- Reduced Heat Impact: Water jet lowers risk of material heat damage.

- Less Deformation: Cooling minimizes thermal-induced deformations.

- Ablation and Splatter Reduction: Water jet washes away molten particles, reducing surface damage.

- Versatility: Suitable for diverse materials, including hard alloys.

- High Precision: Achieves smooth, precise machining surfaces.

Disadvantages of Water-Assisted Laser Technology

- Complex Setup: Requires additional components, increasing complexity and maintenance.

- Material Limits: Effective on materials with specific thermal conductivity.

- Slower Speed: Coupling water jet and laser slows processing.

Advantages of Traditional Laser Technology:

- Wide Application: Established use in cutting, welding, marking, and more.

- High Processing Speed: Faster for efficient production.

- Material Adaptability: Versatile across various metals and non-metals

Disadvantages of Traditional Laser Technology:

- Heat Impact: May cause heat-related damage, especially in sensitive materials.

- Limited Precision: Precision affected by heat and optical constraints.

Applications of Water-Assisted Laser Technology:

- Precision Cutting: Suitable for intricate and precise cutting tasks.

- Hard Materials: Processes hard and brittle materials like ceramics and alloys.

- Sensitive Materials: Ideal for heat-sensitive materials due to reduced thermal impact.

- Surface Cleaning: Used for precise cleaning and preparation of surfaces.

- Medical Devices: Applied in manufacturing medical instruments and implants.

Technical Parameters

Nozzles made of sapphire/Ruby, as these materials’ hardness enables the generation of a long, stable water jet over a long period of time

Diameter range: 20-100 µm

Pure deionised and filtered water

Water consumption is low due to “hair thin” jet: approx. 10 litres/hour at 50 -800 bar pressure.Resulting forces exerted are negligible (<0.1 N)

Diode pumped solid state pulsed Nd:YAG lasers with pulse durations in the micro- or nano-second range, operating at 1064 nm or 532 nm

Average laser power ranges from 20 W to 400 W

1803,2006,Huachuang Building

1803,2006,Huachuang Building

0086 18623135040

0086 18623135040

13500373464

13500373464