World Wide Suppliers of Industrial Sapphire&Ruby Precision Parts

Sapphire to Metal for Fluidic,Metrology&Medical Components

ISO 9001:2019 Mfg&Managment Certified Companies

-

- Sapphire Lens

- IPL Light Guides

- Sapphire Prism

- Zirconia Ceramic Parts

- Single Crystal Silicon Carbide(SiC 6H/ 4H)

- Optical Windows

- Optical Lens

- Sapphire Substrate&Wafer

- CMM Styli - Probe Tips

- Sapphire Orifice Jewel

- Sapphire Windows

- Jewel Bearing

- Sapphire Tube&Rods

- Balls&Semisphere

- Ruby Orifice Nozzle

- Sapphire&Ruby Assembly Parts

- Sapphire&Ruby Nozzle

- Custom Shaped Sapphire Parts

our Material

Contact Details

Chonghong Industries(Microwork)Ltd.

1803,2006,Huachuang Intl Commerce Building

Honghuang 10th Road Jiangbei District

Chongqing China 400020

Tel: (0086-023) 67937146Fax: (0086-023) 89119130

Cellphone:0086-18623135040

Sapphire

How is Sapphire Glass Manufactured?

The manufacturing process of sapphire glass, most commonly done using the Verneuil process (also known as the flame fusion method), involves heating powdered aluminum oxide until it melts and then slowly cooling it to form a crystalline structure. This precise process results in sapphire glass, which has the same hardness and optical characteristics as natural sapphire, but is more economical to produce in large quantities.

Main Characteristics of Sapphire Glass

Sapphire glass, sometimes referred to as sapphire crystal or synthetic sapphire, is a transparent material composed of crystalline aluminum oxide (Al2O3). While it shares the same chemical structure as natural sapphire gemstones, it is synthetically produced to meet the demands of modern industries. Known for its remarkable hardness and resistance to scratches, sapphire glass is utilized in a variety of applications, particularly those that require high durability and clear optical performance.

Types of Sapphire Glass

Transparent Sapphire Glass

This is the most common type of sapphire glass, used in watches, camera lenses, and optical windows where clarity and scratch resistance are essential.

Colored Sapphire Glass

By adding trace elements during production, sapphire glass can be made in a variety of colors, such as blue, green, and yellow. These colored variants are often used in decorative applications and jewelry.

Sapphire Lenses

Sapphire lenses are used in microscopes, telescopes, and camera systems due to their high optical clarity and durability.

Sapphire Substrates

Sapphire wafers are commonly used as substrates in the electronics industry, especially for LED manufacturing and semiconductor production

|

Physical Properties |

|

|---|---|

|

Crystalline Structure |

Rhomboedral Hexagonal Single Crystal |

|

Composition |

AI2O3 |

|

Purity |

99.99% |

|

Cleavage |

Conchoidal |

|

Density |

3.99-3.98 g/cm3 |

|

Disclosation Density |

109-108/m2 |

|

Thermal Properties |

|

|

Melting Point |

2320K |

|

Softening Point |

2070K |

|

Specific Heat |

7.5*102 J/Kg*K at 300K |

|

Thermal Conductivity |

40W/m*K ┴ at 300K |

|

Thermal Expansion |

6.2*10-6/K// C-axis 5.4*10-6/K ┴ C-axis |

|

Mechanical Properties |

|

|

Hardness |

Mohs9 Knoop 2200 face // C-axis,knoop 1800 face ┴ C-axis |

|

Youngs Modulus |

4.4*1011 pa at 300K |

|

Modulus of Rupture |

4.0*108Pa at 300K |

|

Compressive Strength |

2.1*109Pa at 300K |

|

Tensile Strength |

1.9*108Pa at 300K |

|

Poissons constant |

0.30 |

|

Chemical Properties |

|

|

Acids and alkalis attack |

0 to 570K |

|

Porosity |

0 |

|

Electrical Properties |

|

|

Dielectric Constant |

10.6 electric field // C-axis at 300K,8.6 electric field ┴ C-axis at 300K |

|

Electrical Resistivity |

109Ω*m at 770K,104Ω*m at 1270,10Ω*m at 2270K |

|

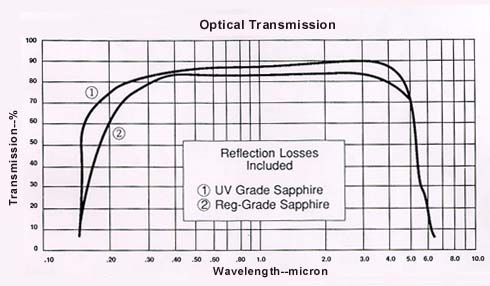

Optical Properties |

|

|

Refractive Index nD at 0.5893μm |

1760 face // C-axis , 1.769 face ┴ C-axis |

|

Dispersive Power(nF-nC) |

0.011 λf=0.4861μm,λc 0.6563μm |

|

Transmission,Disc Thickness |

1 mm |

|

-Visible Light |

Excellent |

|

-Infrared |

85%0.75-5μm,70% 5.5μm,50% 6μm |

|

-Ultraviolet |

80%0.4-0.3μm,60% 0.28μm,50% 0.2μm |

|

|

Common Applications of Sapphire Glass

Camera Lenses

Medical Devices

Laser Optics

Get a Free Quote for Custom Sapphire Glass Parts and Solutions

Whether you need sapphire glass components for optical lenses, semiconductor applications, or industrial machinery, Chonghong microwork can provide customized solutions. Contact us for a complimentary quote tailored to your specifications.

Why Sapphire Glass? Key Advantages

The superior qualities of sapphire glass make it an ideal material for high-performance applications:

There are various forms of sapphire glass, each designed for specific uses:

Request Your Free Quote for Sapphire Glass Components Today

At Chonghong microwork, we specialize in delivering high-quality, custom sapphire glass solutions to meet the specific needs of your business. Contact us today to discuss your project and receive a free, no-obligation quote.

Sapphire glass ranks 9 on the Mohs scale, making it one of the hardest materials available. This extreme hardness ensures high resistance to scratches, making it a preferred choice for products that are subject to frequent wear, such as luxury watches and smartphone screens.

Biocompatibility

Optical Windows

Scratch Resistance: Its extreme hardness ensures protection against scratches, making it suitable for surfaces that require long-term durability.

Optical Performance: With minimal distortion and high transparency, sapphire glass is perfect for applications that require clear and precise optics.

Durability: Sapphire glass can withstand significant environmental challenges, including heat, pressure, and chemical exposure, making it more durable than standard glass.

Thermal Stability: Due to its ability to withstand high temperatures without deformation, sapphire glass is ideal for use in high-temperature environments.

Biocompatibility: Its use in medical devices and implants underscores its safety and non-reactive properties when in contact with living tissues.

1803,2006,Huachuang Building

1803,2006,Huachuang Building

0086 18623135040

0086 18623135040

13500373464

13500373464